Photo by Iqram-O-dowla Shawon on Unsplash

AI for Accurate Transformer Diagnostics

Adopting AI tools for Transformer Diagnostics

Are you a Technology Enthusiast? intrigued by the prospect of elevating your technological expertise to address the most intricate engineering dilemmas? If so, you've landed at the perfect destination—don't let a single moment pass you by. Join the realm of Engineering and immerse yourself in the very heart of cutting-edge AI algorithms.

Introduction

A transformer stands as a pivotal linchpin within the power system, entrusted with the task of conveying and disbursing electricity generated from renewable energy sources. In the pursuit of an operationally seamless and trustworthy electricity utility plant, transformers assume an indispensable role demanding substantial focus. In the recent past, conventional diagnostic approaches for transformers—such as short-circuit tests, frequency responses, and insulation assessments employing meters—have prevailed. Regrettably, these techniques fall under the category of offline diagnosis methodologies. While their precision and sensitivity are commendable, they fall short in promptly identifying nascent transformer malfunctions, consequently squandering both human effort and resources. The exigency of this predicament has paved the way for the integration of AI tools, leveraging their adept data mining capabilities and robustness to preemptively pinpoint faults, thus facilitating timely maintenance interventions.

The application scope of AI methodologies extends to encompass an array of techniques designed to extract insights from Dissolved Gas Analysis (DGA) data, thereby enhancing the efficacy of diagnostic procedures. From towering main transformers to the ubiquitous medium and low-voltage distribution counterparts, these devices occupy pivotal positions across the expansive power grid. Within the context of a distribution network characterized by nonlinearity, uncertainty, and heightened complexity due to the burgeoning influence of renewable energy sources, the preservation of transformer safety and reliability emerges as an imperative of paramount significance.

Fault detection using AI

AI algorithms, particularly machine learning and data analysis techniques have shown great promise in transformer diagnostics. They can help detect faults, predict potential failures, and optimize maintenance schedules. Here are some ways AI algorithms are used for transformer diagnostics:

Dissolved Gas Analysis (DGA): DGA is a widely used technique to monitor the health of transformer insulation by analyzing gases dissolved in the insulating oil. AI algorithms can analyze historical DGA data to identify patterns and anomalies that indicate different fault types. Machine learning models can predict the type of fault and its severity based on gas concentration ratios, helping to schedule maintenance proactively.

Vibration Analysis: AI algorithms can process vibration data from accelerometers placed on transformers to detect mechanical issues, such as core and coil movement, loose components, and winding deformation. By analyzing the frequency spectrum of vibrations, AI models can identify abnormal patterns and predict potential mechanical failures.

Partial Discharge (PD) Monitoring: Partial discharges within a transformer indicate insulation breakdown and can lead to more severe faults if not addressed. AI algorithms can analyze PD data collected from sensors to detect patterns and trends that signify insulation degradation. This enables early intervention to prevent further damage.

Temperature and Load Monitoring: AI algorithms can analyze historical temperature and load data to identify trends and correlations. By tracking changes in temperature and load patterns, machine learning models can predict potential overheating issues and recommend load adjustments or maintenance actions.

Image Analysis: Visual inspections of transformers can be enhanced using AI-powered image analysis. Cameras and drones equipped with image-processing algorithms can capture images of transformer components, such as insulators, bushings, and cooling systems. AI can detect signs of corrosion, physical damage, and oil leaks, facilitating early maintenance.

Pattern Recognition: Machine learning algorithms can be trained to recognize fault patterns in data, such as waveforms from transformer currents and voltages. By comparing real-time data to trained models, AI can identify deviations that indicate emerging faults.

Predictive Maintenance: AI algorithms can combine various data sources, including historical maintenance records, sensor data, and environmental conditions, to predict the optimal time for maintenance. This helps utilities avoid unplanned outages and reduce maintenance costs.

Fault Classification and Diagnosis: AI models can classify faults based on data inputs, such as current and voltage waveforms. By analyzing these patterns, AI can diagnose faults like short circuits, winding defects, and insulation breakdowns.

Data Fusion: AI algorithms can integrate data from multiple sources, such as DGA, PD, temperature, and load, to provide a comprehensive view of transformer health. This holistic approach enhances diagnostic accuracy and reduces false alarms.

Remote Monitoring: AI enables remote monitoring of transformers through IoT-connected sensors. Data transmitted from these sensors can be analyzed in real-time, allowing for immediate intervention in case of critical issues.

AI techniques used for transformer diagnostics

Advanced techniques in intelligence are now extensively applied in the realm of transformer fault diagnosis, yielding compelling outcomes. Diverging from conventional approaches, artificial intelligence methods emulate the decision-making and problem-solving abilities akin to living organisms, adapting them to address real-world complexities. These approaches are adept at tackling broader problem descriptions that often lack specific structural details, rendering them particularly suited to unravel intricate challenges such as transformer fault diagnosis. The application of intelligent techniques serves to mitigate the uncertainties inherent in traditional Dissolved Gas Analysis (DGA) methods arising from boundary issues, unresolved codes, or scenarios involving multiple faults.

Artificial intelligence strategies are harnessed to diagnose oil-immersed transformers, aiming to bolster the diagnostic accuracy of transformers while augmenting the stability and dependability of their operation. The techniques are subdivided into;

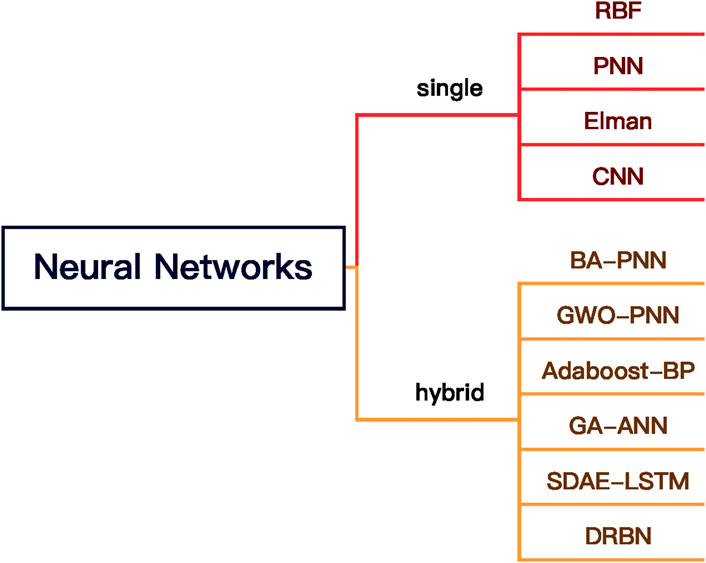

Neural Networks

Neural networks can adequately approximate arbitrarily complex nonlinear relationships, and after learning from the initialized inputs and their relationships, it can also infer unknown relationships from unknown data, thus allowing the model to generalize and predict unknown data.

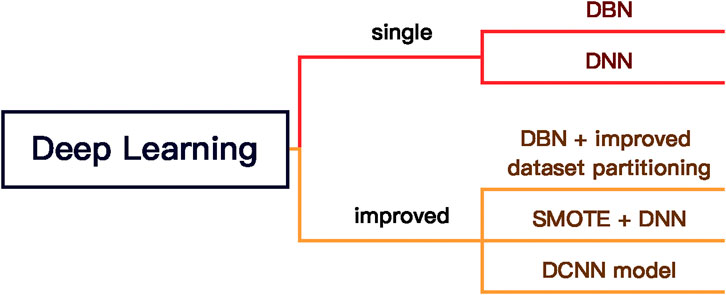

Deep learning

Deep learning performs more layers of nonlinear operations and breaks the traditional neural network limit on the number of layers. The feature data learned by deep learning models are more intrinsically representative of the original data, which greatly facilitates classification and visualization problems.

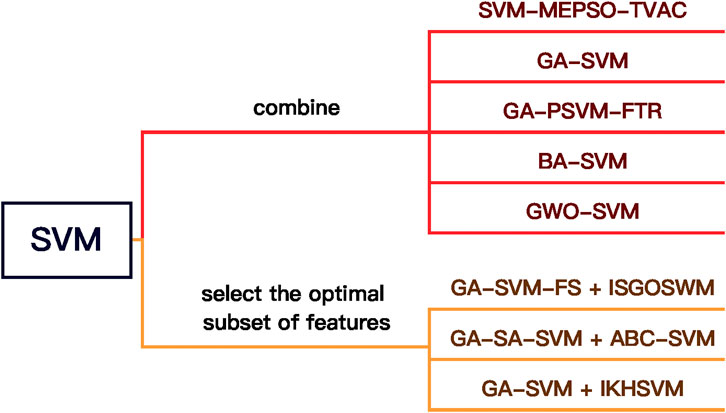

Support Vector Machine(SVM)

Support vector machine (SVM) is also widely used in fault diagnosis to improve fault classification accuracy. SVM is an effective method to deal with large dimensionality of independent variables without recalculating from initial conditions to obtain new decision boundaries.

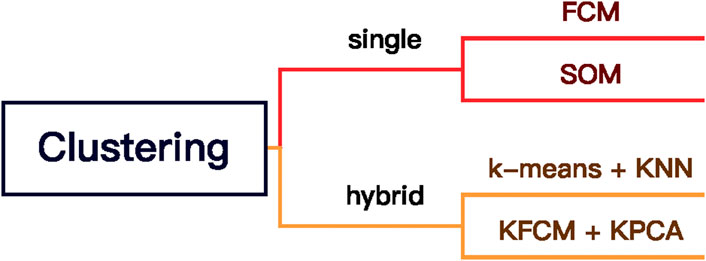

Clustering

Many clustering algorithms are widely used in transformer fault diagnosis. Clustering algorithms can be combined with DGA data or combined with other data to be able to classify transformer faults effectively. The fuzzy c-means clustering algorithm (FCM clustering algorithm) is a classical method of clustering. Still, the clustering accuracy for dissolved gas data is not high enough to classify transformer faults accurately.

Other techniques include (Logic regression, Association rules, Decision tree, D-S Evidence theory, Expertized guided machine learning, Fussy logic, Gene expression programming, Hidden Markov model, and Semi-supervised autoencoder with an auxiliary task).

Conclusion

It's important to note that adopting AI tools for transformer diagnostics requires a robust data infrastructure, appropriate sensors, and expertise in both power systems and AI technologies. Regular validation and calibration of AI models are essential to ensure their accuracy and reliability. As AI continues to evolve, the potential for enhancing transformer diagnostics will likely expand, leading to more efficient and effective maintenance practices.

Thank you for embarking on this thrilling exploration as you have navigated through the documentation. I trust you enjoyed the experience. If you're interested in delving deeper into the concepts, please don't hesitate to get in touch.